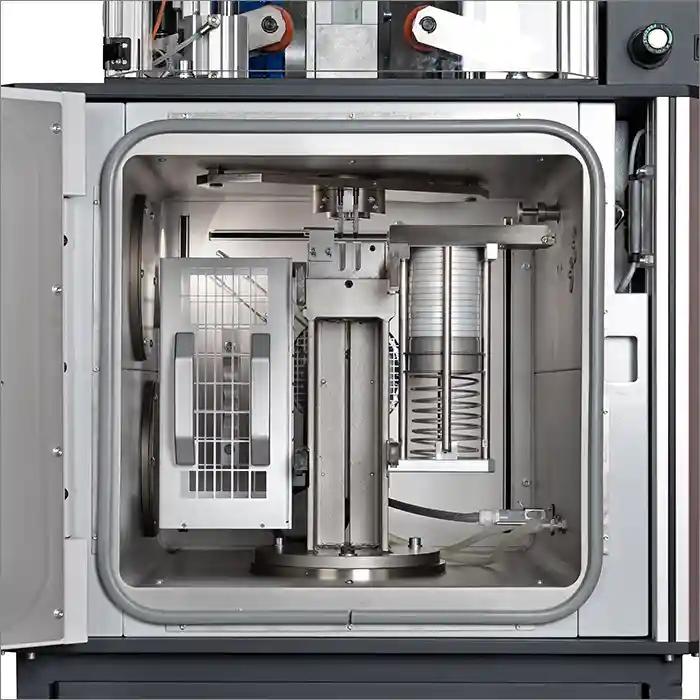

Drop Weight Impact Testing Machine

Impact Tester for Plastics, Composite, Light Alloys and Components

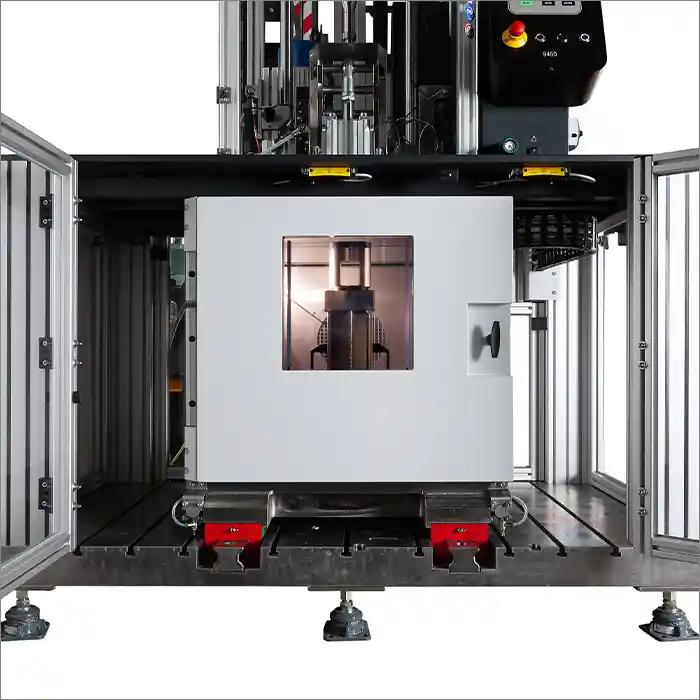

Instron Dynatup drop weigh impact testing machine next generation is the Instron 9400 Series. A drop weight impact testing machine is used to determine the energy required to break or damage a material in which a defined weight falls onto a specimen or a component from a specific height and with a specific impact energy and velocity.

The Instron® 9400 Series drop weight impact testing machine complies with all the main impact testing standards ranging from 0.3J – 1800J

Puncture Test Method and Other Impact Test Methods

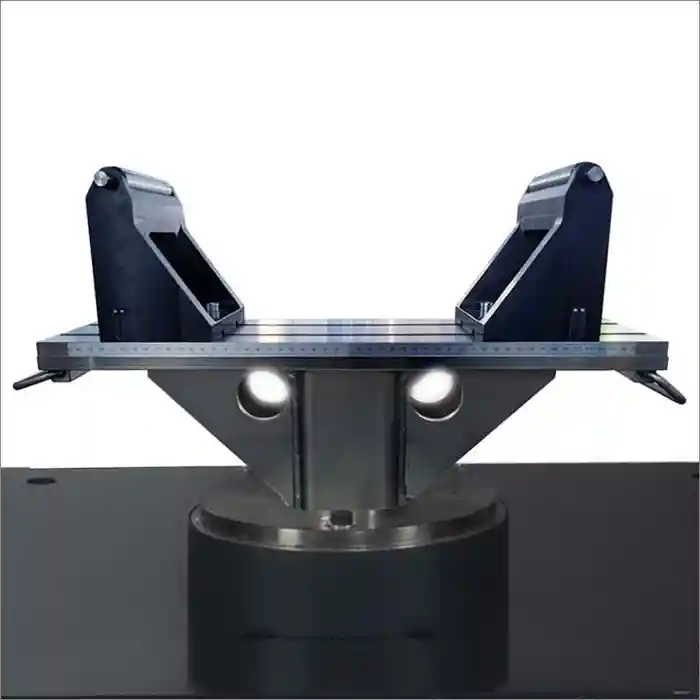

Puncture resistance test, CAI test (Compression After Impact), Tensile Impact Test, 3 Point Bending Test and Wedge Peel Impact Test are the most common drop weight impact test methods. They determine the toughness of polymers, load-deflection curves and total energy absorption of impact events. The main ISO and ASTM standards for impact test of plastics are: ASTM D3763 multi-axial impact test, ISO 6603 for the puncture resistance test method, ASTM D7136 for the CAI test method, ISO 11343 for the wedge peel impact test method, ISO 8256 for the tensile impact test method.

SIMPLER

Start Testing Faster

The intuitiveness of Bluehill® Impact software with the touchscreen dashboard simplifies day-to-day activities: users are guided through the entire testing process with step-by-step instructions, ensuring tests remain repeatable, simple, and error-free

Simplified Flexibility

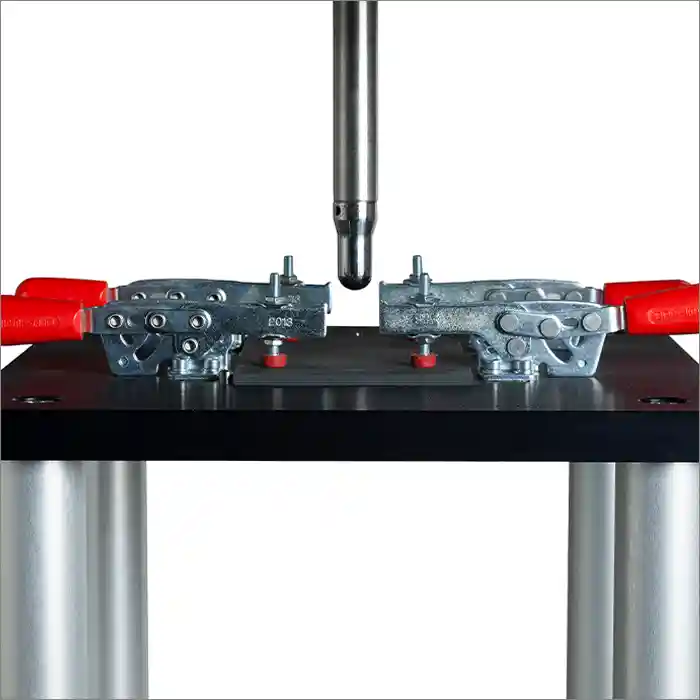

Enhance your Instron drop weight impact testing machine's versatility with a wide range of easily changed supports, masses, fixtures and accessories for puncture resistance test, tensile impact test, and wedge peel impact test along with compressive and component test

Speed up Collaboration

Move from task to task: easily share test methods and results within your Company or your Customers with Bluehill Impact file management system

SMARTER

Extended Capabilities

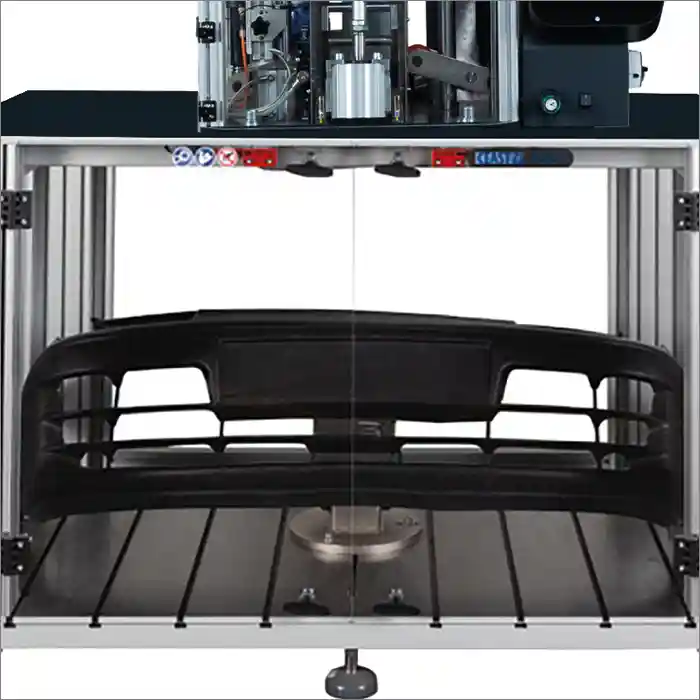

Instron drop weight impact testing machine energy capacities and test space meet the most commonly performed impact test methods specific in Raw Materials Industries, Automotive, Aerospace-Aviation, Defense, Electronics and Consumer Products over a wide range of materials

Handle the Most Demanding Analysis

The 9450 drop weight impact testing machine capabilities can be expanded to include 24 m/s impact velocity, extra wide test chambers and high-speed cameras to never miss an impact test event

Faster Time to Market

With automated testing, newly developed materials can be continuously tested and validated. The reduction in testing cycles allows your Company to bring your products to market faster

Impact Testing Machine Parts, Accessories and Options

Available Models